Press release -

BPW electrifies top logistics companies and trailer manufacturers with generator axle for transport cooling that is really cost-effective

- BPW ePower proves economy and sturdiness over 350,000 test kilometres

- Homologated by leading trailer manufacturers – EU type approval from summer

- Intelligent control of energy generation reduces influence on truck and brakes

- Hardly any additional consumption, no intermediate charging necessary, battery balancing while on the road

Electric refrigeration machines, powered by the recovery of traction and braking energy, are designed to finally make temperature-controlled transport quieter, more climate-friendly and more sustainable. But is it cost-effective? BPW provided proof in a large-scale test with leading refrigerated logistics companies: the results after more than 350,000 test kilometres convince even sceptics of the economic efficiency of the ePower generator axle.

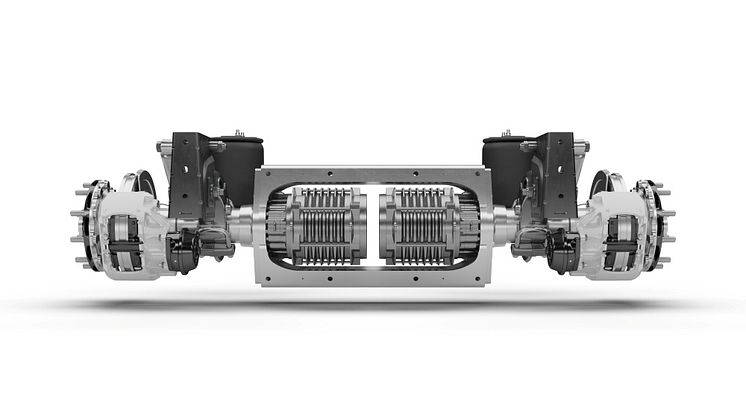

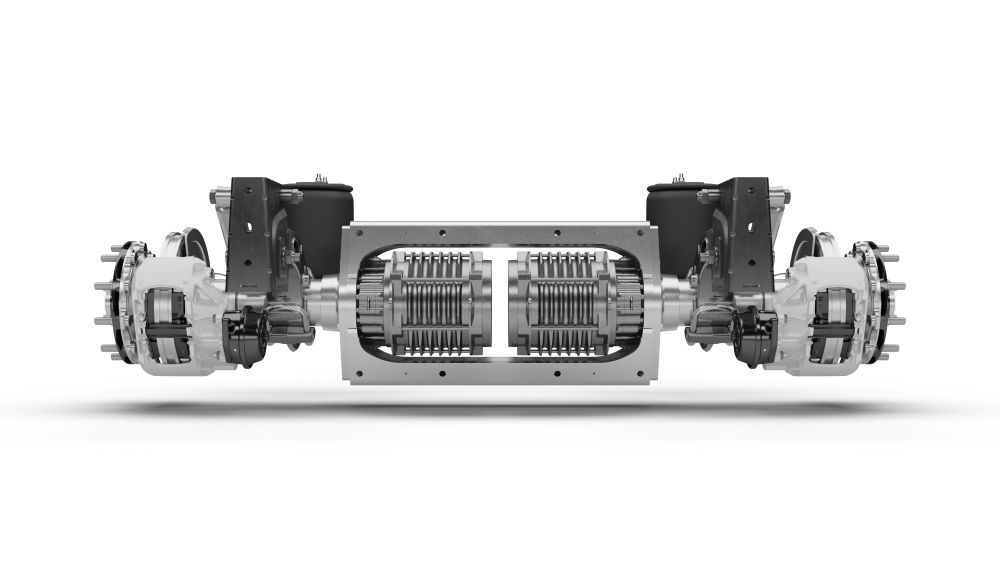

Wiehl, 15 August 2024 --- BPW Bergische Achsen KG loves to set standards with innovations for the digitalisation and electrification of transport. The family-owned company took an uncharacteristically long time to develop ePower, a generator axle for trailers that generates electricity for emission-free transport cooling while on the road: it is no mean feat to connect the axle to a generator - but it is quite a feat to design it as part of the unsprung mass in such a way that it works reliably in every driving situation - and will do so for the entire life of the trailer. This explains the design of the axle, which supplies power to electric and hybrid refrigeration machines as an integral part of the Thermo King AxlePower system. In ePower, two generators are in operation instead of one. This "power from two hearts" is not inhibited by an energy-sapping differential. This explains the efficiency as well as the performance and safety reserves of the system, which has been designed to be particularly robust in harsh operating conditions. Another special feature is intelligent recuperation control, which constantly adapts to the driving situation. It activates at speeds as low as 15 km/h; thanks to driving situation recognition, the system prefers to use braking and downhill driving to charge the batteries of the cooling unit. This relieves the burden on the tractor unit. Towing mode is also used to generate electricity before the battery reaches a critical state of charge.

BPW is therefore breaking new design ground with its ePower generator axle. But how does the system perform in everyday refrigerated transport - and how economical is it in reality? To answer this question, BPW and its partner Thermo King have involved more than ten leading European refrigerated logistics companies and trailer manufacturers in the development process: the test vehicles have now covered 350,000 test kilometres on European and South African roads to investigate the performance of the system in typical application scenarios.

The result convinced even the sceptics: ePower delivered maximum efficiency both in pure distribution transport and also mixed with long-distance journeys. For example, one of the test trailers provided cooling non-stop for 20 weeks in test operation using only the energy generated in stop-and-go traffic and when travelling downhill. This is where ePower was able to capitalise on another special feature: stationary intermediate charging - such as overnight - is possible, but not technically necessary. Battery management takes care of battery balancing, which is intended to counteract the chemical wear and tear of the batteries that occurs in electric vehicles while driving. This avoids costly downtime.

Electric refrigerated logistics without changing transport processes and fleet management

Therefore ePower can be used in distribution logistics without having to change the existing logistics processes and fleet management. And: procurement of the entire system, including the refrigeration unit and battery packs, will be amortised within the usual service life of the trailer. For use in densely populated areas, combination with a purely electric cooling system has proven to be economically optimal, while a diesel-electric hybrid unit is recommended for mixed traffic. Larger batteries would only be required for purely long-distance operation, which is why the diesel is currently still the most economical cooling drive in this case.

Franz Gerhard Jungkamp, Head of Operations/Logistics, L. Stroetmann Foodstuffs: "In our experience, ePower is the first consistently practical solution for temperature-controlled transport: the generator axle allows emission-free transport refrigeration without compromising on efficiency and logistical processes. As a wholesale partner of the EDEKA Group and operator of our own wholesale and retail stores, environmentally friendly logistics solutions are an integral part of our growth strategy. This is why we have intensively supported the development of a trailer that is optimally adapted to the 350 kilometre operating radius of our refrigerated logistics. Even the test phase went better than anticipated, the battery is so powerful that the cooling system doesn't have to be connected to the power grid even during four-hour waiting periods."

Katarina Kermelk, Product Manager at BPW, adds: "ePower fulfils the highest automotive safety standards in accordance with ISO 26262 and has been homologated by the leading European trailer manufacturers. Series production began back in October 2023 and the first manufacturers are expecting European type approval in the summer. This means that it will be possible to deliver fully electric and hybrid refrigerated trailers with ePower without individual approval for the first time."

The series production of ePower is now the starting point for BPW to explore further electric applications in trailers. Katarina Kermelk: "With ePower, we have solved the design challenges associated with energy recovery. This makes many developments possible. For BPW, the principles of efficiency, safety and reliability always apply."

BPW will be exhibiting the ePower axle at IAA Transportation from 17th to 22nd September in Hannover (BPW Group exhibition booth in Hall 26/A30).

Related links

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen KG is the parent company of the BPW Group. With around 1,500 employees, including around 100 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs around 7,000 staff in 27 countries and achieved consolidated sales of 1.731 billion euros in 2022. www.bpw.de/en