Pressemeddelelse -

CEMOS makes its way into the XERION large and system tractors from CLAAS

Just in time for the launch of the XERION 12 Series, CEMOS – the world’s leading operator assistance and process optimisation system for tractors – is now available in the highest performance class up to 650 hp.

Assistance for every operator

First unveiled at Agritechnica in 2017 and awarded a silver medal by the Innovation Commission, until now CEMOS for Tractors has only been available for CLAAS standard tractors with CMATIC continuously variable transmission. But the dialogue-based, self-learning operator assistance and process optimisation system will also be available for the XERION 4200, 4500, 5000, 12.590 and 12.650 large and system tractors from model year 2024. The system can be retrofitted to existing machines with a CEBIS touchscreen terminal as a software update.

CEMOS for Tractors helps the driver optimise ballasting, tyre pressure, engine and gearbox management and implement settings to enable them to perform fieldwork as efficiently and productively as possible and to an exceptionally high standard. While work is underway, when parameters such as the traction resistance of the soil, relief or net traction ratio often change (especially during tillage), CEMOS continuously compares the recorded actual variables with the achievable optimum and suggests further adjustments to the driver aimed at improving efficiency and productivity. Furthermore, the resulting reduction in fuel consumption leads to a significant reduction in CO2 emissions. An added advantage is the enhanced level of soil protection, since adjustments to ballasting and tyre pressure combined with the integrated Terranimo® app reduce the ground contact pressure, thereby avoiding undue, inefficient and harmful wheel slip.

CEMOS is now available for the XERION 12 Series as well as the XERION 5000, 4500 and 4200 and can be retrofitted to existing machines fitted with the CEBIS touchscreen.

DLG-approved optimisation potential

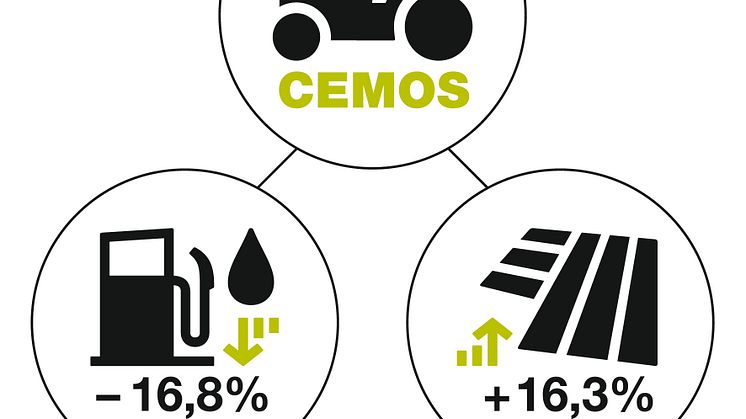

During a DLG test in 2020 (DLG Test Report 7096) with two AXION 870 CMATIC tractors with trailed cultivators, CEMOS for Tractors was found to reduce fuel consumption by up to 16.8 per cent and increase area output by up to 16.3 per cent compared with an experienced field of international drivers. By continuously comparing sensor data on actual ground speed, tractive power, wheel slip, fuel consumption, engine speed and transmission ratio, along with other variables, CEMOS was shown to provide valuable assistance even for expert drivers – so even the best can be even better. Through this process of continuous data synchronisation, the system can precisely identify and quantify optimal operating states and variables during dynamic field work and then, using a dialogue-based interface, suggest ongoing adjustments to the driver. This is what makes CEMOS different from other purely static systems without the self-learning function.

The dialogue-based approach ensures that the driver is actively involved in all optimisation measures and so is continuously learning at the same time. So CEMOS could also be described as an on-board training programme for experienced and less experienced drivers alike.

Third CEMOS strong point: soil protection

CEMOS for Tractors has incorporated the Terranimo® function as standard since summer 2022, enabling the tractor-implement settings to give even greater priority to soil protection. Terranimo® is a simulation model for calculating and visualising the risk of harmful compaction developed by Bern University of Applied Sciences (BFH-HAFL) in cooperation with the Agroscope Research Institute in Reckenholz, Aarhus University in Denmark and the Swedish University of Agricultural Sciences (SLU). Its algorithms are based on decades of combined knowledge. They are merged with the parameters stored by the driver in CEMOS, such as soil type and condition, working depth, field condition (uncultivated, shallow or deep cultivated), implement, tyre type, ballasting and so on, so no additional data has to be entered when using Terranimo®.

Using this information and the engineering mechanics generated by CEMOS, such as static and dynamic axle loads, Terranimo® calculates the risk of compaction for three separate soil layers, which is then displayed in the CEBIS terminal. CEMOS uses this information to make further recommendations to the driver about ballasting and tyre pressure optimisation that support a more soil-friendly driving style.

Emner

Kategorier

About CLAAS

CLAAS (www.claas-group.com) is a family business founded in 1913 and is one of the world’s leading manufacturers of agricultural machinery. The company, with Head Office in Harsewinkel, Westphalia, is the European market leader for forage harvesters. CLAAS dominates the European market in another core segment as well – combine harvesters. CLAAS also holds the top spots in global agricultural technology with its tractors as well as its agricultural balers and grassland harvesting machines. Cutting-edge agricultural information technology also forms part of its product range. CLAAS employs more than 12,100 staff worldwide and generated a turnover of 4.9 billion euros in 2022.