Pressemeddelelse -

500,000 CLAAS combine harvesters – a unique success story

- 1936: Presentation of the first European combine harvester, the combine-threshing-binder (MDB) with cross-flow principle; 1,400 machines were built until 1943

- 1946: Introduction of the SUPER with the transverse-longitudinal flow principle, followed in 1953 by the JUNIOR

- 1950: Export of the first CLAAS combine harvester to South America (Argentina, Brazil and Uruguay)

- 1952: Sale of the first CLAAS combine harvester to North America – the buyer is a Canadian farmer

- 1953: Presentation of the first self-propelled CLAAS combine harvester, HERCULES (later renamed SF)

- 1958: CLAAS SUPER AUTOMATIC with hydraulic operation

- 1958: Introduction of the popular EUROPA and COLUMBUS models - around 60,000 units of both are built together

- 1962: Presentation of the large combine harvester MATADOR with a cutting unit width of up to 6.0 m

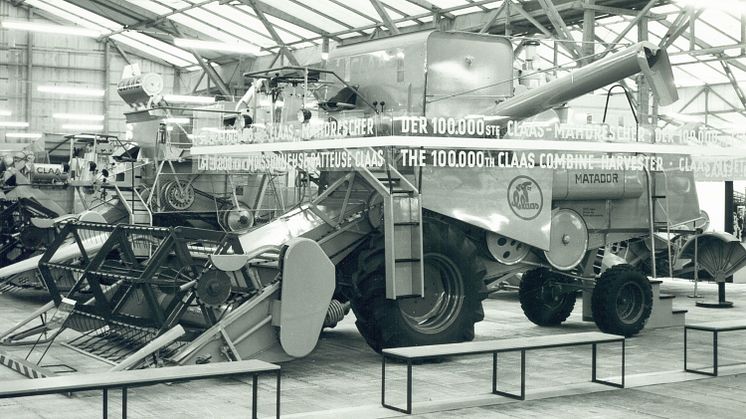

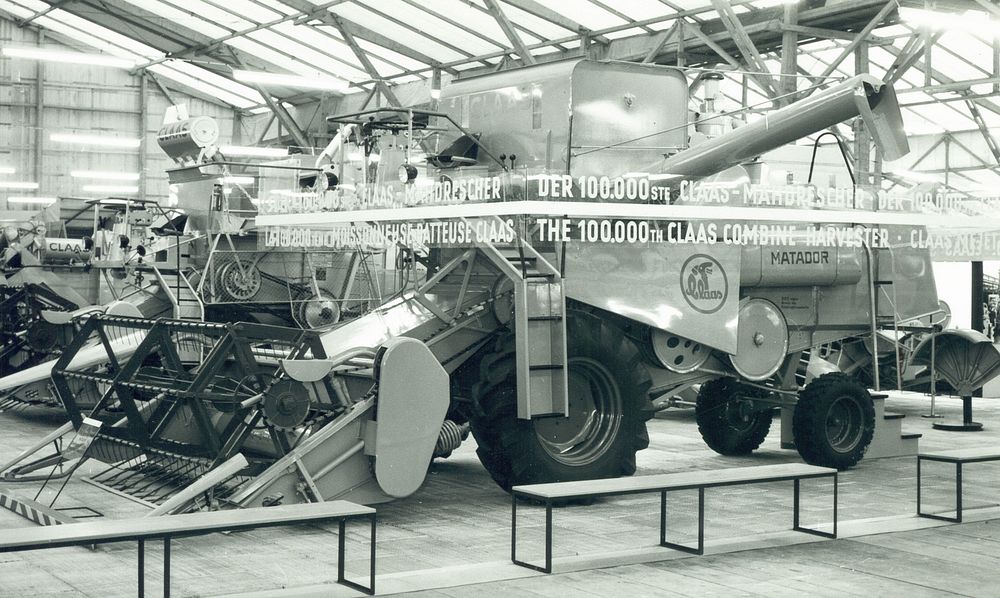

- 1962: Production of the 100,000th CLAAS combine harvester

- 1967: Start of production on a new generation of combine harvesters with models such as SENATOR, MERCATOR (from 1969) and PROTECTOR (from 1969) as well as the smaller models CONSUL, COSMOS, COMET, CORSAR and from 1971 COMPACT; more attention to design and operator safety

- 1966: began contract manufacturing of combine harvesters for the Ford Company and the North American market

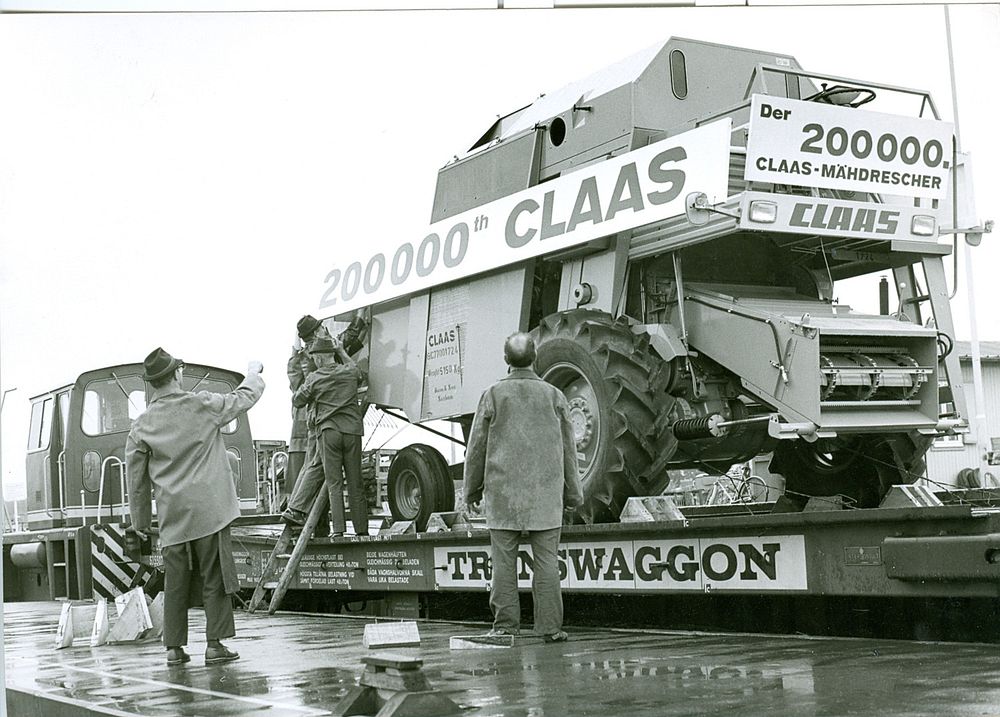

- 1968: 200,000 CLAAS combine harvesters have left the factory in Harsewinkel. The jubilee machine, a SENATOR, was sold to UK and was in use there until at least 2017.

- 1971: Introduction of the DOMINATOR series with models 80 and 100 and modular design

- 1974: With the throughput control device, an electronic driver assistance system was introduced into a CLAAS combine harvester for the first time

- 1979: Introduction of the new DOMINATOR 6 series

-

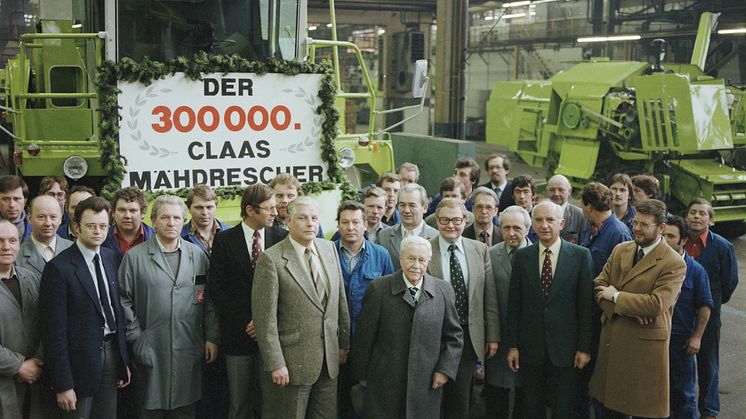

1979: CLAAS breaks the mark of 300,000 combine harvesters built

- 1981: Introduction of the DOMINATOR 8 series and the DOMINATOR CS series with cylinder separation

- 1983: Introduction of 3D cleaning for increased harvest performance on slight slopes

- 1985: Introduction of the electronic on-board information system

- 1987: COMMANDOR CS TERRA TRAC with rubber track chassis

- 1990: AUTO CONTOUR enables automatic lateral and longitudinal control of the cutting unit

- 1990: CLAAS builds the 350,000th combine harvester, a DOMINATOR 108 MAXI

- 1991: Combination of Yieldometer yield data and GPS coordinates

- 1993: Introduction of the APS/MEGA threshing system into the DOMINATOR six-walker and five-walker combines for up to 30 percent more throughput

- 1995: Premiere of the LEXION 480 at Agritechnica - for up to 40 t/h throughput, with new VISTA cab with CEBIS and yield mapping with AGROCOM MAP

- 1997: Introduction of TERRA TRAC technology into the LEXION series

- 1997: Commissioning of cutterbar and corn picker production at the Törökszentmiklós plant, Hungary.

- 2000: Start of production of the MEDION combine harvester with 4 and 5 walkers

- 2001: Commissioning of the combine harvester plant in Omaha, Nebraska (USA)

- 2003: Presentation of the LEXION 500 series

- 2003: CLAAS builds the 400,000th combine harvester – a LEXION 480

- 2005: the new LEXION 600 capable of harvesting up to 70 t/h

- 2008: Introduction of the TUCANO series below the LEXION

- 2010: the new AVERO replaces the DOMINATOR in Europe in the lower performance segment

- 2011: the LEXION 700 TERRA TRAC enables road travel of up to 40 km/h

- 2013: Presentation of the LEXION 780 with DYNAMIC COOLING and CEMOS AUTOMATIC - this is followed by a series of further CEMOS expansion stages that make the system a leader in the field of combine harvester automation.

- 2013: Construction of the 10,000th TUCANO and the 450,000th CLAAS combine harvester – a LEXION.

- 2015: Introduction of 4D cleaning in the LEXION 700

- 2016: the 50,000th LEXION rolls off the assembly line in Harsewinkel as an anniversary machine

- 2019: Presentation of the new LEXION 5000 – 8000 series with up to 790 HP, expanded CEMOS assistance and new CONVIO and CONVIO FLEX Draper cutting units

- 2019: Start of production of the DOMINATOR 370 hybrid combine harvester in Gaomi - for the local market and export markets in Asia, Africa and South America

- 2019: Color scheme for North America changed from yellow to seed green

- 2020: The 10,000th CLAAS CROP TIGER rolls off the assembly line in Chandigarh, India

- 2021: Presentation of the new TRION, which will initially be launched in Europe in 2022

- 2022: the DOMINATOR 260 expands the construction program in Gaomi

- 2022: The German-American Chamber of Commerce awards the LEXION 7000 - 8000 as “The Coolest German Thing Made in the USA”.

- 2023: the EVION completes the new CLAAS combine harvester family

- 2023 October: Start of the first filling of LEXION and TRION with hydrogenated vegetable oils (HVO) as a sustainable fuel at the Harsewinkel plant

- 2024 October: A new era of connectivity begins with the new CLAAS connect – also for CLAAS combine harvesters.

Did you know? CLAAS combine harvester rarities and funny facts at a glance…

- With only 18 units built, the CLAAS DOMINATOR CS TERRA TRAC / COMMANDOR CS TERRA TRACis one of the least frequently built combine harvesters from CLAAS.

- The JUMBO prototype was built in 1970 in 22 units. Although equipped with groundbreaking technologies such as top emptying, the product was not developed to series production. All prototypes were scrapped.

- Another rarity is the CLAAS Bautz TITAN. After CLAAS took over Bautz in 1969, a few examples of the CLAAS Bautz Titan combine harvester were built and marketed in Seedgreen CLAAS branding until production was phased out in 1972. However, further development of this design type was not pushed forward as the new DOMINATOR was already in preliminary development at CLAAS.

- The GARANT was the last pulled-type combine harvester developed at CLAAS. Only around 1,000 units of the machine, which worked using the longitudinal flow process, were built between 1972 and 1978.

- The SUPER series, which was a much older development, was sold until 1979. This makes it the CLAAS product that has been in the product range for the longest time – more than 30 years.

- The CLAAS HUCKEPACK was the only CLAAS combine harvester with two engines. Since the 12 hp chassis engine of the system tractor produced from 1956 to 1960 was not powerful enough, the combine harvester body was fitted with its own industrial engine from VW with 22.5 hp (later 27 hp). The combine harvester structure was the basis for the EUROPA, which was introduced in 1958.

- From 1988, a combine harvester body was also tested during the preliminary development of the XERION. However, this was not developed to series production. What was striking was that the threshing unit was located directly behind the cutting unit and only the grain-chaff mixture was transported by elevator into the cleaning system saddled on the chassis. The prototype can be viewed today in the CLAAS museum depot - but without the associated cutterbar.

- CLAAS combine harvesters have been available in different colorsover the decades. The light blue color of the MDB was followed by a silver color from the SUPER series through the SF (HERCULES) to EUROPA and COLUMBUS. Since it was too blinding in the sun for farmers on the southern hemisphere, CLAAS introduced the color “Austral Green” in 1961. However, this only lasted for a short period: for the 1967 season, all CLAAS machines were given a Seedgreen color scheme for the first time. For export to Hungary, CLAAS combine harvesters were painted yellow for a long time - to match the demands of the largest customer IKR, a state-operated farming entreprise. CLAAS LEXION combine harvesters marketed in North America from 1997 to 2019 were also yellow. CLAAS combine harvesters were available in blue and red and with brand-specific type designation for the North American Ford agricultural machinery sales network (1966 - 1984) and for Massey Ferguson (1989 - 1995).

- Before CLAAS decided on Seedgreen in 1966, a color scheme in matt silver with red accents and red lettering was in direct competition to replace Austral green. As part of the decision-making process for the future paint color, a SENATOR was painted in an alternative color scheme.

- At the DLG exhibition in Munich in 1968, CLAAS showed a very early interpretation of a “steering system” as a world first: a remote-controlled SENATOR combine harvester. The idea came from the passionate hobby model pilot Walter Claas, who was responsible for marketing and training at the time. The system was tested in a sand pit in the Boomberge hills, a long-term test area south of Harsewinkel. The demonstration in the ring at the DLG exhibition attracted a lot of attention and stimulated discussion among scientists and practitioners, but this approach was not further developed.

Emner

Kategorier

About CLAAS

CLAAS (www.claas-group.com) is a family business founded in 1913 and is one of the world’s leading manufacturers of agricultural machinery. The company, with Head Office in Harsewinkel, Westphalia, is the European market leader for forage harvesters. CLAAS dominates the European market in another core segment as well – combine harvesters. CLAAS also holds the top spots in global agricultural technology with its tractors as well as its agricultural balers and grassland harvesting machines. Cutting-edge agricultural information technology also forms part of its product range. CLAAS employs more than 12,000 staff worldwide and generated a turnover of 6.1 billion euros in 2023.