Pressemeddelelse -

500.000 CLAAS combines around the world: Six chapters of CLAAS combine harvester histories

Today, combine harvesters handle the vast majority of harvesting of grain, grain corn, legumes and other threshing crops worldwide. They harvest up to 100 t of wheat per hour or more, use less and less fuel, document the harvest quantity for specific areas and, thanks to machine intelligence, adjust themselves more and more often.

As one of the world's leading providers in this business, CLAAS has been shaping the development and construction of combine harvesters for almost 90 years with groundbreaking innovations and products. To be successful in global competition for so long requires not only ideas, solid engineering skills and practical relevance, but also the highest quality products, highly professional service and an excellent supply of spare parts. However, one by one…

Chapter 1: Trailed CLAAS combine harvesters from MDB to GARANT

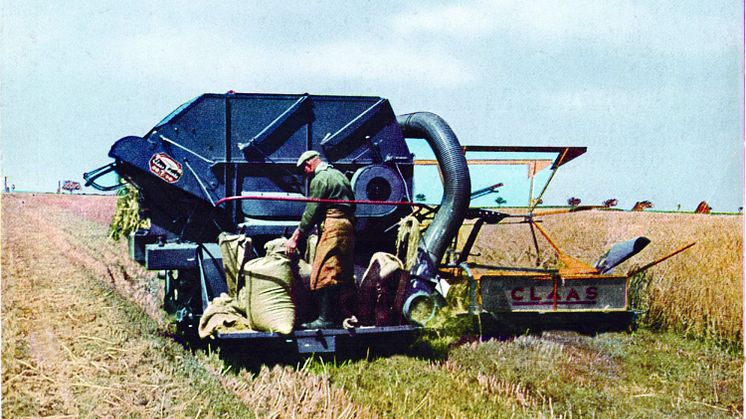

Before the introduction of self-propelled combine harvesters, trailed, tractor-driven machines dominated the fields, replacing stationary threshing machines. In 1936, the family company CLAAS brought the first European combine harvester, the combine thresher or MDB for short, onto the market. This laid the foundation for nationwide rationalization and thereby revolutionized grain harvesting in Europe. This cross-flow combine was a combination of a self-tie and a threshing unit, with the threshing unit housed between the header and the binder. After cutting, the grain was transported via a conveyor cloth to the threshing drum, where a conveyor chain diverted the straw and threw it onto the walker. It then went through two cleanings before the harvested grain was put into sacks at the bagging stand and the straw was tied into straw bundles. Around 1,400 examples of this type were built until production was stopped in 1943 due to the war.

The big hit followed in 1946 with the chic, silver-colored SUPER: like the smaller SUPER “JUNIOR” that followed in 1953, it worked according to the transverse-longitudinal threshing principle and was constructed in a revolutionary and robust self-supporting body or shell construction. Threshing performance and operator comfort were further significantly improved by these models, especially with the hydraulic operation introduced for the SUPER in 1958 under the name AUTOMATIC - which made the trailed SUPER a true one-man machine. Now it was also possible to "automatically" unload from the tractor seat. Continually improved, the SUPER was built in Harsewinkel more than 65,000 times by 1978 and was also exported in large numbers to overseas countries. A SUPER for a Canadian customer was the first CLAAS combine harvester in 1952 in North America, and from 1950 onwards the first machines were also shipped to Brazil, Uruguay and Argentina.

The MDB and its successors, such as the SUPER and SUPER AUTOMATIC, not only significantly increased harvest performance, but also improved worker safety through integrated functions. But the era of trailed combine harvesters was coming to an end in the 1970s. The last CLAAS development of this type was the GARANT with the longitudinal threshing principle, which was built from 1968 to 1972. At this time, the self-propelled guns from Harsewinkel had already begun their triumphal march...

Chapter 2: The first self-propelled machines and a real giant of his craft

The birth of self-propelled combine harvesters at CLAAS came in 1953 with the introduction of the HERCULES, which was renamed SF for “self-propelled” in the same year. In Harsewinkel they had recognized the signs of the times: thanks to their own engine, self-propelled vehicles were no longer dependent on the often limited power of the towing tractor, and they were also more maneuverable, more compact and more powerful. The SF worked with an air-cooled four-cylinder engine and was able to handle a cutting width of 4.20 m, which was enormous for the time. It was also more versatile because, in addition to grain, it could also harvest peas, rapeseed, corn, clover and grass.

As an economical alternative, CLAAS introduced the piggyback in 1957 - an equipment carrier that could be converted into a self-propelled combine harvester thanks to suitable bodies, a 2.10 m wide cutting unit and a driver's seat that could be rotated through 180 degrees.

Meanwhile, demand for self-propelled combine harvesters had skyrocketed across all company sizes. CLAAS responded and added the three-walker models EUROPA and COLUMBUS to the product range in 1958 and 1959. The EUROPA received the piggyback threshing mechanism and became the best-selling self-propelled CLAAS combine harvester to date. For small businesses, the COLUMBUS was able to provide cutting widths from 1.80 m - both models together were built more than 60,000 times.

In 1962, a bang sounded from Harsewinkel that made the agricultural technology industry sit up and take notice: the new CLAAS MATADOR, with its 87 hp, 4.5 square meters of walker area, 2,690 l grain tank and up to 6.0 m wide cutting unit, beat everything previously known. It was considered a true giant of its time, and is still an impressive machine today. Its impressive appearance and performance were also reflected in its name after the introduction of the slightly smaller MATADOR STANDARD. From then on it was a matter of competing with the MATADOR GIGANT from CLAAS. The gap to COLUMBUS and EUROPA was closed in 1964 with the MERCUR from the four-walker class.

Chapter 3: The Age of Senators, Corsairs, Comets and Protectors

From the late 1960s onwards, the shape and appearance of agricultural machinery became increasingly important. In 1967, CLAAS logically ushered in a new era in combine harvester construction with the SENATOR. Large protective panels and covers made of metal not only ensured greater safety, but also gave the combine harvester a stylish appearance. Edges sloping backwards shaped the contours of the new machine, with the grain tank and engine cover forming a harmonious line. What was also new was the seed green paintwork of the machine and the new company logo, which from then on adorned all CLAAS agricultural machines. In addition, for the first time, customers were able to optionally order a cabin instead of the open driver's platform with the SENATOR.

When the SENATOR was introduced, CLAAS had already built 185,000 combine harvesters in the factory halls in Harsewinkel. To achieve this, the production halls were constantly expanded and modernized. In the 1960s, CLAAS introduced state-of-the-art manufacturing methods modeled on the automotive industry, including the test bench process, painting individual parts for improved corrosion protection to increase the quality and reliability of the machines, and an electronically supported main control center that optimized the entire production process.

In addition to design and performance features, user comfort has always become the focus of development. Hydrostatic steering was therefore part of the standard equipment, as was a drive with a detachable power band - a world first for combine harvesters.

Two smaller combine harvester models followed in 1968 and 1969: MERCATOR and PROTECTOR. At the same time, CONSUL, COSMOS, COMET and CORSAR replaced the aging EUROPA and COLUMBUS machines by 1970. In 1971, the new COMPACT series followed with three models, which enabled even the smallest farms to switch to self-propelled technology.

From 1969 onwards, CLAAS was the only western manufacturer to be very active and successful in the Hungarian market. Until the fall of the Iron Curtain in 1989, CLAAS was able to sell a total of around 5,000 combine harvesters in the country, which until then had been dominated by large state-owned companies. This was made possible primarily through compensation transactions: CLAAS concluded various license agreements with Hungarian manufacturing companies that supplied components such as cabins and corn pickers.

Parallel to the market launch of the first seed-green combine harvester fleet, a new, industry-defining revolution was already being developed in Harsewinkel, the name of which would shape combine harvester construction for more than 50 years...

Chapter 4: The DOMINATOR era

The year 1971 marked a significant turning point in combine harvester construction at CLAAS and at the same time ushered in a new era of mechanized grain harvesting. As early as 1969, the development of a new class of combine harvesters was initiated in Harsewinkel - the DOMINATOR. Two years later, the first 5-walker DOMINATOR 80 was introduced, followed a year later by the DOMINATOR 100 with a wider threshing drum and six walkers. The engine was now located between the grain tank and the driver's cab and could therefore drive the threshing drum directly and efficiently. A world first was the hydrostatic drive available for the DOMINATOR 80. In 1974, an electronic driver assistance system was introduced into CLAAS combine harvesters for the first time with the electronic throughput control device - the forefather of the later CEMOS system.

At the same time, the introduction of the DOMINATOR series marks a milestone in combine harvester production at CLAAS, as modular construction is used for the first time. Identical or similar assemblies and modules could be used on different models with different widths. This resulted in a significant reduction in costs and inventory levels within production.

With the successor models DOMINATOR 85 and 105, introduced in 1975, the intensive walker with one or two controlled packing tines per straw walker was introduced. The next big thing, however, was the DOMINATOR 6 series in 1979 with a groundbreaking design and a completely newly developed, fully integrated cabin, which raised comfort for the driver to a new level, especially thanks to single-lever operation for the cutting unit, reel, drum speed and travel speed as well as the central information system. As early as 1981, the DOMINATOR 8 series was further improved with a new comfort cabin, multifunctional handle and air conditioning as well as further developed monitoring and control elements. The cabin received a spring-loaded driver's chair, air conditioning and heating. Thanks to attributes such as versatility, performance and reliability, the combine harvesters consolidated CLAAS' dominance in the European combine harvester market. From the end of the 1970s onwards, large quantities of DOMINATOR were even exported to Hungary - as part of compensation transactions for wheat and other agricultural products.

CLAAS broke new ground with the DOMINATOR CS series, which was added to the range in 1981 and later renamed COMMANDOR CS. The globally unique CS cylinder threshing system set new standards in throughput performance, supported by up to 250, and later even up to 330 HP engine power. From 1987 onwards, these could be ordered on the North American market with an optional rubber crawler chassis. However, it would still be a few years before the company developed its own TERRA TRAC crawler tracks.

Over the years, the DOMINATOR combine harvesters have been continuously improved. Groundbreaking innovations such as the on-board informant, 3D cleaning and the Auto Contour cutting system guidance have consolidated the reputation of the harvesting technology specialist from Harsewinkel as an innovation leader in the industry. In some regions of the world, the name DOMINATOR even becomes a synonym for the word combine harvester. In 1991, in combination with the Yieldometer, it was possible for the first time ever to record GPS position and yield on a combine harvester.

In 1993, CLAAS replaced the larger DOMINATOR walker combines with the MEGA series. The new MEGA threshing mechanism with an additional drum promised up to 30 percent more performance and a smoother crop flow through the threshing mechanism. As of this year, over 350,000 CLAAS combine harvesters had already been built and shipped to harvest fields and farms around the globe.

Just two years later, CLAAS was to push the limits of previously known threshing performance with a completely new generation of combine harvesters...

Chapter 5: LEXION – Beginning of a new age

Thanks to CEBIS, important work data could be saved on a chip card for the first time and edited and printed out on the computer in the office. GPS position and yield recording could easily be further processed into graphical yield mapping. With the automatic machine settings in CEBIS, it was possible to relieve the driver's workload and significantly increase performance, regardless of long working days. Together with other driver assistance systems such as the automatic reel system, another big step towards automation was taken.

The seed-green technology leadership was continued with the introduction of the LEXION 400 walker combine harvester and the successor series LEXION 500, 600 and 700 - the latter with an innovative and fuel-saving DYNAMIC COOLING system - while series such as MEDION, TUCANO and AVERO are introduced below the LEXION. In 1997, CLAAS consolidated its relations with Hungary by taking over a production site in Törökszentmiklos, which had supplied CLAAS with combine harvester components since 1977. The CLAAS combine harvester business was also making progress in North America – although not in the company colors. In a joint venture with Caterpillar, LEXIONs were built in a yellow-black color scheme at a joint combine plant in Omaha, Nebraska and sold in the USA and Canada.

The year 2019 also marked a turning point for CLAAS in North America: the yellow-black color scheme disappeared and all CLAAS combine harvesters have since been sold again in the typical seed green color scheme. The increase in North American business and market share there, as well as the decision to use only green seeds in North America since 2019, impressively demonstrate the continued growth and strategic orientation of CLAAS on the international market.

Chapter 6: A completely new combine harvester family

The year 2019 marked another highlight in the history of CLAAS combine harvesters. The newly introduced LEXION 5000, 6000, 7000 and 8000 series, led by the high-tech LEXION 8900 flagship with an impressive 790 hp, have since set new standards in combine harvester technology. The main innovations are the new APS SYNFLOW and APS SYNFLOW Hybrid threshing and separation systems. In particular, the threshing drum, which has grown to a diameter of 755 mm, in conjunction with the large 600 mm feed drum, significantly increases the threshing performance and further improves efficiency thanks to the straight, gentle crop flow. Cleaning and straw management have been further developed, and new productivity levels are also achieved with grain tank volumes of up to 18,000 l and unloading performance of up to 180 l/sec. Thanks to DYNAMIC POWER, the engines provide exactly the amount of power that is currently needed - thereby further increasing efficiency. A significant contribution to this is made by the further improved CEMOS AUTOMATIC, which has been expanded to include further technologies such as CEMOS AUTO CLEANING, CEMOS AUTO THRESHING, CEMOS AUTO SEPARATION and CEMOS AUTO HEADER and is combined with further automatic functions such as AUTO CROP FLOW, AUTO SLOPE or CRUISE PILOT. The LEXION thus once again lives up to its reputation of being the combine harvester to compete with.

In parallel with the new LEXION generation, CLAAS presented two new series of draper type cutterbars in 2019: CONVIO and CONVIO FLEX are not only suitable for harvesting ground-level threshing crops and grain, but also for rapeseed threshing. The optimized crop flow with the ear first also increases threshing performance and reduces vibrations in the threshing mechanism.

The year 2019 also marked a turning point for CLAAS in North America: the yellow-black color scheme disappeared and all CLAAS combine harvesters have since been sold again in the typical seed green color scheme. The increase in North American business and market share there, as well as the decision to use only green seeds in North America since 2019, impressively demonstrate the continued growth and strategic orientation of CLAAS on the international market.

In 2021, CLAAS redefined the medium combine harvester performance class. The compact TRION with three series is based on the global market-tested genetic features of the LEXION and brings state-of-the-art technologies such as CEMOS or TERRA TRAC into this high-volume segment for the first time. Three series with five walkers, six walkers, APS Hybrid with single rotor and APS Hybrid with double rotor are in a class of their own and make it possible to offer the right package for every customer thanks to a variety of configuration options. Be it soil-friendly TERRA TRAC drives, various grain tank sizes and grain tank outlet pipe with pivoting spout, smooth-running belt retraction or CEMOS driver assistance like the LEXION – customers can put together exactly the machine they need for their operational needs. The new cab with a swivelling driver's seat, which has also been used on the LEXION since 2022, is also impressive. Just in time for the start of production of the TRION, CLAAS commenced combine harvester production in a new assembly hall at the main plant in Harsewinkel, which was built in record time and uses the most modern production processes with automotive standards, such as driverless transport systems for final assembly.

The introduction of the EVION in 2023, which brings the DNA of LEXION and TRION to the lower class of combines and completes CLAAS's combine portfolio as the successor to TUCANO and AVERO, underlines CLAAS' commitment to continuous innovation and industry-leading performance – not only for large scale farms and contractors, but also for future-oriented family farms. With the three five-walker models, the combine harvester family is complete for now.

Conclusion: Performance and efficiency - an impressive development

In 1936, the first European combine harvesters from CLAAS harvested 1.5 tons of grain per hour, with diesel consumption of well over 5 liters per hour. The threshed grain first had to be filled into bags at a bagging stand and then loaded onto carts using hard physical labor. Later, grain tanks and grain tank outlet pipes took over this work - a great relief and basis for massive increases in productivity. The MATADOR GIGANT with a 6.0m wide cutting unit achieved a throughput level of 3.3 t/h with a consumption of around 3.0 liters per ton.

Today, the most powerful CLAAS combine harvesters harvest more than 100 tons of wheat per hour under optimal conditions and only consume 1.0 to 1.5 liters per ton. This means that since 1936, productivity has increased almost a hundredfold, with a significant reduction in energy input.

In the future, new innovations, even more CEMOS machine intelligence and even more extensive connectivity will continue to increase both productivity and efficiency. Automation will be a key.

CLAAS will continue to be one of the world's leading pacesetters and drivers of progress.

Emner

Kategorier

About CLAAS

CLAAS (www.claas-group.com) is a family business founded in 1913 and is one of the world’s leading manufacturers of agricultural machinery. The company, with Head Office in Harsewinkel, Westphalia, is the European market leader for forage harvesters. CLAAS dominates the European market in another core segment as well – combine harvesters. CLAAS also holds the top spots in global agricultural technology with its tractors as well as its agricultural balers and grassland harvesting machines. Cutting-edge agricultural information technology also forms part of its product range. CLAAS employs more than 12,000 staff worldwide and generated a turnover of 6.1 billion euros in 2023.