Pressemeddelelse -

500.000 CLAAS combine harvesters: Behind the Scenes

The preparation of the major production anniversary for CLAAS combine harvesters took more than a year. Numerous levers had to be set in motion for the global rollout of several anniversary machines.

First it was a figure, then an idea, and finally a project: One – 500,000 – half a million CLAAS combine harvesters. But how do you celebrate such a number anniversary appropriately?

A look at the company archives shows how such projects were approached decades ago. Up until the 300,000th CLAAS combine harvester, these were generally completely "normal" trade fair or customer machines. From 2003 and the 400,000th CLAAS combine harvester, special paintwork came into play - based on the JAGUAR model - and to this day they are a natural part of CLAAS anniversaries. In the past, the special machines for combine harvester anniversaries always came exclusively from Harsewinkel. After all, the main plant has always had the largest share of the global machine inventory - which is still the case today with more than 485,000 combine harvesters built.

Nevertheless, the world has changed since 2003. It has become smaller, more interconnected. And the CLAAS production network has also grown – as have production figures in the international plants in Omaha (Nebraska, USA), Gaomi (China) and Törökszentmiklós (Hungary), where CLAAS cutterbars and corn pickers are built.

500,000 CLAAS combine harvesters: It was a long way from the idea to the design and finally the painting and assembly to the stickers.

In order to take this change into account, the decision was quickly made: there should not just be one anniversary machine, but several. There should be at least one LEXION, TRION, EVION and DOMINATOR each with different types of cutterbars - and eventually even a few more. Because countries where there are no CLAAS production sites should and wanted to be able to take part in the anniversary. So the eye-catching machines will not only roll across German fields in the coming harvest, but will also be at North American and Chinese trade fairs and will prove their skills to farmers in Australia, France, the UK, Denmark, Poland and Romania.

From design to finished machine: cross-departmental collaboration and external support

But before that could happen, a design draft had to be drawn up. The anniversary machines were to use their appearance to build a bridge between the past and the present. The most important eras in the history of CLAAS combine harvesters were silver and seed green - and CLAAS combine harvester no. 400,000, a LEXION 480, with its silver color scheme, referred to the important era from 1946 to 1961, when CLAAS became the European market leader and developed unforgettable milestones such as the SUPER and the SF. The colors chosen were therefore silver and seed green - but with metallic paint for exclusive brilliance in sunlight. For the finish, CLAAS Industrial Design designed large stickers with overlapping CLAAS and 500000 lettering. The CLAAS lettering is designed to be partially transparent, with hundreds of the well-known CLAAS knotting hooks punched out as a pattern – the first CLAAS patent from 1921 and for a long time a defining symbol of the CLAAS company logo.

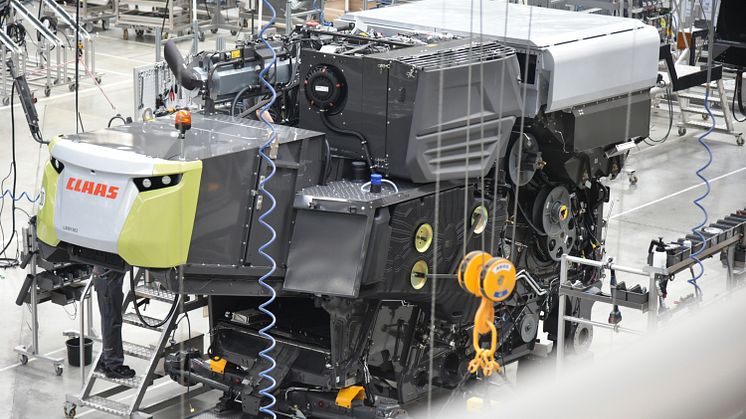

Mankiewicz Gebr. & Co. was available as a supplier for the special paint. The Hamburg-based company already produces the standard paints for CLAAS and can therefore draw on a lot of experience in mixing the right colors. The painting itself was a challenge: Because many non-conductive materials such as plastic or Alucobond could not be painted using the powder process that is common at CLAAS, the components and parts had to be finished externally using the wet painting process. This meant that more than 60 parts were collected per machine, which had to be removed from production before pre-, basic and final assembly, transported to the painter, finished and then fed back into pre-assembly. This was because the LEXION and TRION were too big to even be painted using paint booths for trucks once assembled. Only the EVION could be painted in a paint booth for trucks and buses, but this also required the dismantling of obstructive attachments beforehand.

In order for the single-layer painted parts to be able to return to assembly undamaged, special frames had to be made in some cases in the production and logistics areas. Particular care was taken during assembly so as not to damage the valuable parts. And so the first anniversary machine was able to leave the factory on May 30, 2024. Now the paint had to dry for a few days before the large, custom-made stickers could be applied. A job for professionals, because the size and position of the stickers were precisely calculated. And of course the stickers had to be applied to the panels without bubbles.

The CLAAS lettering is partially transparent thanks to the punched-out knotter hook pattern, the seed green “500000” stands out from the metallic paintwork of the machine.

The logo: More than a Machine

All CLAAS combine harvesters for the 2025 product year will receive a "More than a machine" sticker on the cab door, the Sales Edition will be recognizable by larger "More than a machine" stickers on the side panels. The logo covers four important eras in CLAAS combine harvester development: the combine-threshing-binder as the first CLAAS combine harvester and the first European combine harvester and representative of the era of towed combine harvesters at CLAAS, the SF as the first CLAAS self-propelled combine harvester, the DOMINATOR as the most important unit generator to date and the LEXION as the "game changer" first introduced in 1995 and representative of today's modern CLAAS combine harvester family.

Anniversary machines and Sales Edition versions ensure that 500,000 CLAAS combine harvesters will remain visible in the fields of the world for decades to come. Most of them at least until the rollout of the 600,000th CLAAS combine harvester. And possibly much, much longer.

Emner

Kategorier

About CLAAS

CLAAS (www.claas-group.com) is a family business founded in 1913 and is one of the world’s leading manufacturers of agricultural machinery. The company, with Head Office in Harsewinkel, Westphalia, is the European market leader for forage harvesters. CLAAS dominates the European market in another core segment as well – combine harvesters. CLAAS also holds the top spots in global agricultural technology with its tractors as well as its agricultural balers and grassland harvesting machines. Cutting-edge agricultural information technology also forms part of its product range. CLAAS employs more than 12,000 staff worldwide and generated a turnover of 6.1 billion euros in 2023.