Blog post -

Reduce, the second part of the 7R model, light weight

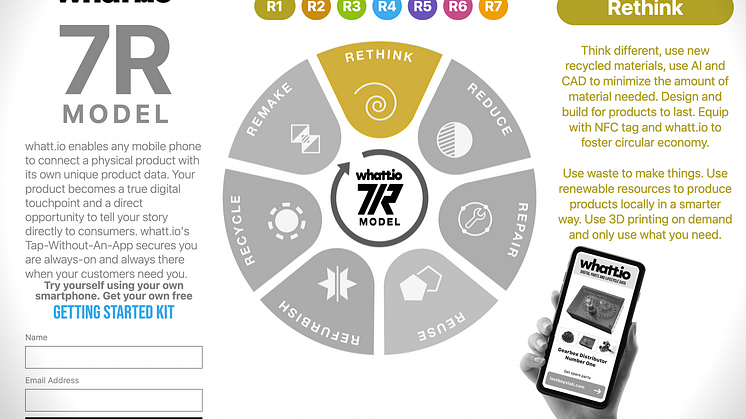

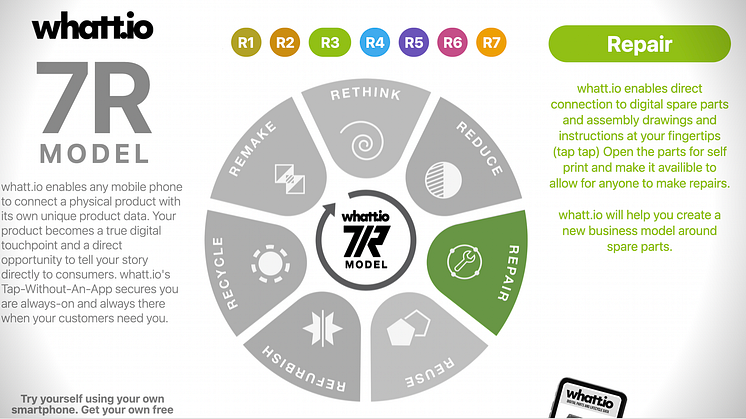

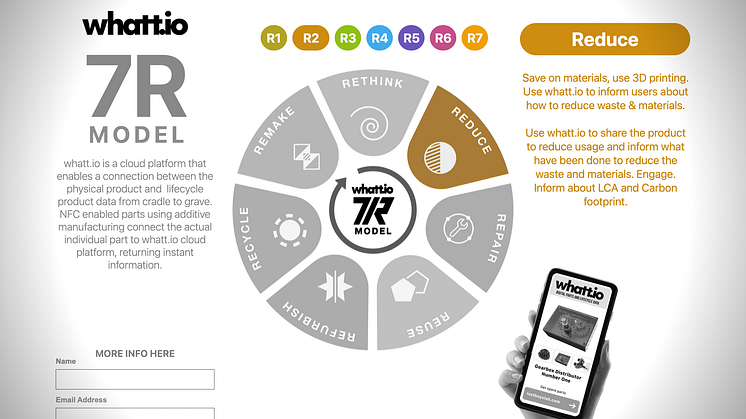

In the second stage of the 7R model, we explore how to reduce our impact and footprint from product development and the designer's perspective. The simpler perspective of the circular economy typically encourages us to follow the conventional three Rs: Refuse, Reduce, and Recycle. However, this approach is primarily focused on single-use plastics and simplifying things for everyday consumers.

As designers, makers, and manufacturers, we need to find ways to reduce material usage, use less energy in production, transportation, and usage, and consistently seek ways to Rethink (the first R in the 7R model) our manufacturing and production of parts and components. Adopting a futuristic view of manufacturing can actually reduce the carbon footprint of a product from cradle to gate. Beyond the "gate" to grave, we must leverage product information to assist end-users in utilizing the product in ways that reduce its environmental impact.

Material reduction is a crucial topic and one of the easiest ways to drastically reduce energy consumption during product manufacturing. When the product is later recycled or disposed of, less material needs to be managed. It's a no-brainer, really.

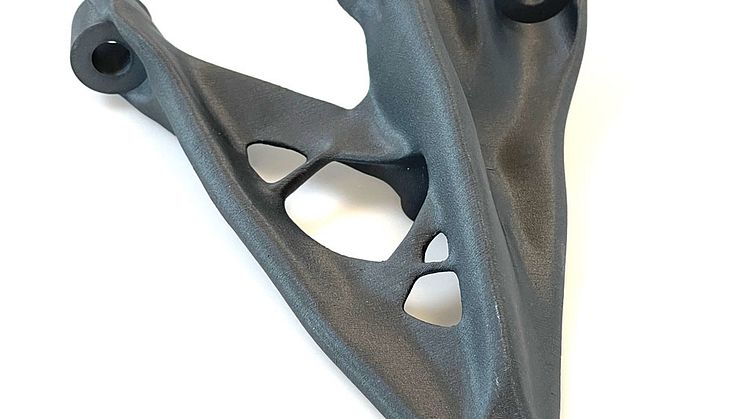

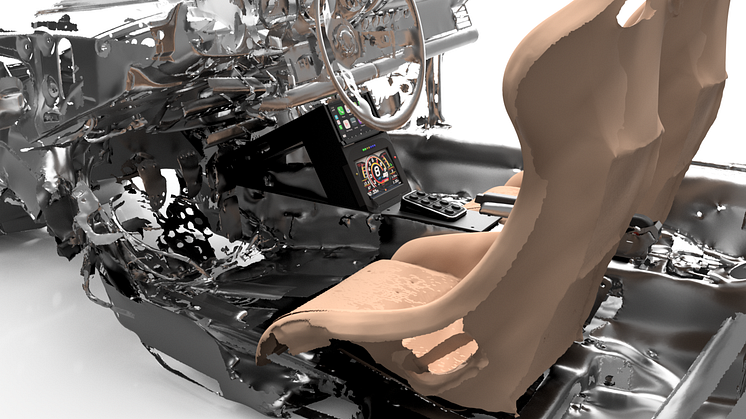

Motor racing serves as an example of how lightweight materials and modern technology can significantly influence design. In this field, weight is key to faster lap times. That's why generative design and super-light materials like carbon fiber and titanium have revolutionized race car design in recent years. Some manufacturers counterbalance a higher vehicle weight with stronger engines, but this introduces unwanted weight. The energy consumption of any moving vehicle is based on both acceleration and deceleration, meaning a heavier vehicle needs a heavier engine, larger brakes, and must account for more G forces in all directions.

The complete shift to electric vehicles in our daily commute isn't solely beneficial. From a Life Cycle Analysis (LCA) perspective, we need to account for all aspects. Electric engines may reduce reliance on gasoline, but the batteries required are significantly heavier than their gasoline counterparts and not as efficient at storing energy. This need for heavier batteries impacts the main body strength of the vehicle, adding weight and necessitating larger brakes. Furthermore, car tires are major polluters, and increased vehicle weight leads to faster tire wear. Harder acceleration and braking, characteristics of electric engines, also contribute to faster tire wear. When we design cars using precious materials like copper, graphite, and cobalt to reduce fossil fuel use, we simultaneously create heavier vehicles that increase road and tire wear, generating more waste.

This complex puzzle isn't easy to solve, but the designer's core objective should be to use recycled materials, bio-materials, and, of course, to keep the moving vehicle as light as possible (without sacrificing safety). Many startups in the electric vehicle industry are seriously considering these "Reduce" aspects and are looking at smaller, more efficient vehicles for city transportation.

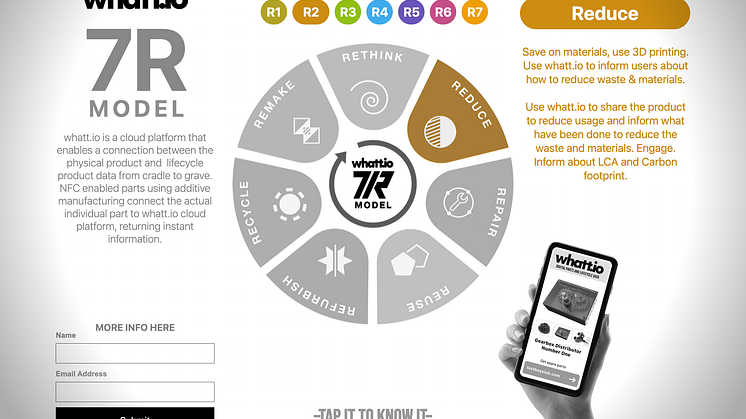

As consumers, we need to know the material composition of batteries, engines, etc., and connecting to a life cycle platform like whatt.io can aid in this. This connection can help other companies understand the material composition of crucial parts that can be reused and recycled. Products need to be able to declare their materials easily, perhaps with a simple tap on a phone using NFC tags or similar identifiers.

Reducing material usage in every single part often means adopting new technology and manufacturing methods, and calculating LCA and carbon footprint impact early on. One such promising technology is FDM 3D printing, provided we're mindful of the type of electricity we're buying!

FDM (Fused Deposition Modeling) is the most common method of 3D printing and is the most suitable for sustainable manufacturing, as it enables the use of recycled and hybrid materials. Whatt.io's developments include gathering information from the production process (including how the electricity is created), enabling automatic calculation of the LCA for the manufacturing process and generating a carbon footprint for each part and the full product.

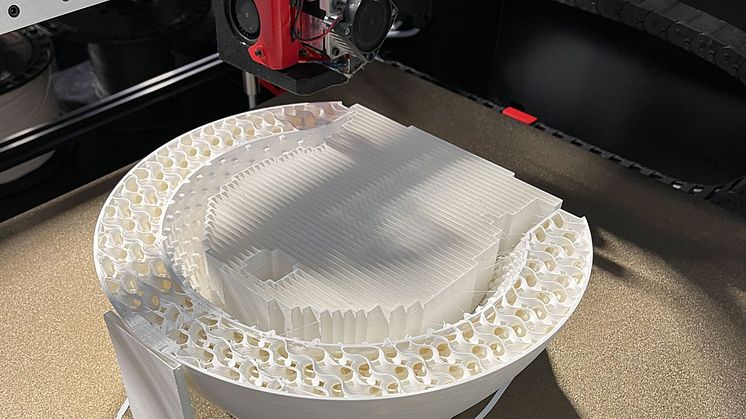

With FDM, materials don't need to be solid at all. The 3D printer can build up an internal structure that reduces material usage by up to 90%, making 3D printing superior to other 3D technologies and all injection molding processes. More advanced methods of reducing material usage, such as generative design, are based on artificial intelligence. This technology is being increasingly utilized and is starting to become a standard tool in most 3D design and mechanical CAD software.

Advanced 3D printers using continuous carbon fiber, such as the Markforged and Onyx with the industrial series like the X7 3D printer, can strengthen a part, replacing other materials. Although cost may be an issue, if reducing materials and lowering weight is a higher priority, continuous carbon fiber is a solution. It also requires much less energy than CNC machining parts out of a large piece of metal, making it a favorable comparison to the use of carbon-reinforced Onyx vs. Aluminum.

In summary, we can use technology and new manufacturing methods available today to create lighter and smarter parts. Adding continuous fibers saves weight, and using infills reduces the material and energy spent on producing a part. 3D printing primarily uses electricity and saves on transportation and storage as it's a distributed manufacturing process in contrast to mass production. Using technology like whatt.io will help in declaring materials used and automatically calculating the carbon footprint for the manufacturing part.