Press release -

Monitoring solution for wind turbine rotor blades

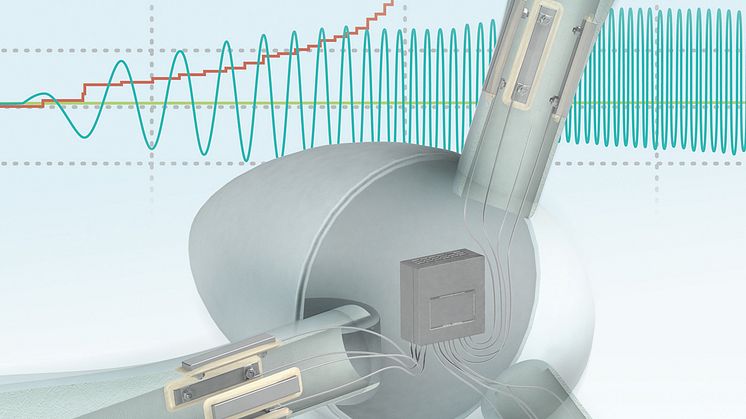

The RBTM (Rotor Blade Tension Monitoring) solution from Phoenix Contact continuously monitors the oscillations of wind power installation (WPI) rotor blades.

As a result of increasingly longer blades, the systems monitoring their loads and oscillations must keep up with rising demands. The monitoring solution utilises strain gauges glued into the rotor blades. These sensors provide measuring data for calculating the mechanical stress imposed on the rotor blades. Freely programmable digital outputs can be used to transmit an alert signal in the event that configured thresholds are exceeded. All data can be made available for performing analyses. Data transfer takes place either via an optional modem or directly via the fieldbus built into the WPI. The monitoring solution can be integrated in virtually any bus environment, including Profinet, Profibus, Modbus, or CAN.

There are two versions available, depending on whether the system is to be introduced as a retrofit or is to be part of the electrical design. The box solution is ideal for retrofitting and comes with a fully preassembled control cabinet ready for mounting in the hub. The SD card solution addresses customers who want to install the controller and I/O modules into the pitch control cabinets.

More information about our technology for Wind PowerTopics

Categories

Phoenix Contact, founded over 80 years ago, is a leading manufacturer of electric connection and industrial automation technology. 12,800 employees, 47 own sales companies and 30 sales partner worldwide ensure customer proximity.

Our work is dedicated to the creation of progress with inspiring, innovative solutions and to a trusting partnership towards our customers and partners with common benefits.