News -

A circular game changer

The Löfbergs group is working to close the packaging loop and contribute to a circular economy. The family-owned company recently conducted a successful test of producing fully recyclable packages made of 50% bio-based polymers. The new packaging will be used by the Danish brand, Peter Larsen Kaffe, and is approved for recycling in Denmark. It is a truly game changing package. Madelene Breiling, Supply Chain Development Manager, has more.

Hi Madelene, is Löfbergs revising its packaging strategy at the moment?

Yes, we are adding the circular approach in order to fully support the EU Strategy for Plastics in a Circular Economy. And to be even more relevant and respond to the demands of customers and consumers going forward.

What has Löfbergs done within the field before?

We have achieved significant progress towards sustainable packaging through history and we have been in the forefront. We proactively follow and are well-informed of changing conditions, regulations, emerging packaging trends and innovations.

Early in the 1990’s, we started phasing out our aluminium and metallized barrier. We downgauged materials that resulted in a reduction of weight. At the same time, we implemented material innovations, that are known today as high-barrier multi-laminates.

Over the years, we have developed a process and a methodology on how to stay contemporary, how to benchmark our products in terms of sustainability, cost, convenience as well as how to secure production capability and quality.

We have also learned that there are no quick wins when it comes to choosing the right sustainable package. This work needs to be tactical, planned, secured and evaluated for us to take the right steps at the exact right time. We cannot afford to fast jump into solutions that are not fully investigated or secured; neither can we afford to risk product quality, to lose production capacity or to make a bad environmental decision.

Is Löfbergs’s project to replace fossil-based plastics still up and running?

Yes, it certainly is. When we started this project five years ago, we set an ambitious goal to phase out all fossil-based plastics and replace them with a greener alternative made from renewable sources. It was a bold statement beyond traditional light-weight initiatives.

Our choice to use bio-based plastics made from renewable raw material has been very successful, as the material has the same chemical and mechanical properties as fossil plastics. That is why it is a good solution suitable for the plastics cycle.

What has Löfbergs achieved so far?

Today, 67% of all the material we purchase come from renewable or recycled sources. We have secured almost 90% of our production volumes, meaning that the major part of our production capabilities is able to run these new greener materials. On item or article level, we present products composed of almost 70% bio-based content.

Why not 100% bio-based?

Due to the fact that coffee packages require many technical and quality properties. Until now, it has not been possible to only use one single polymer, in for example the classic PE (short for polyethylene). If we were to pack frozen bread or grains, products that do not require any high barriers to preserve the quality and taste, then the packaging could easily be done in a single layer material. Nevertheless, we keep pushing for materials, living up to all the circular commitment.

So, what is happening now?

The current overall strategy to work towards plastics from renewable sources will now also commit to act on designing packages for recyclability – on all markets. Timewise, the target is 2030.

Why was this not a part of the original strategy?

We set a realistic goal two years ago to use renewable or recyclable plastics by 2030. The objective is in line with several action plans towards a fossil-free society. Nevertheless, back then the producing industry could not get a straightforward answer or consistent instruction about the recyclability of packaging. There was not a harmonized EU directive or an explaining guideline what kind of polymers and combinations that were accepted for recycling. Today, the local and national governments have at least presented design guides for each market, explaining which polymers the recycling facilities can or will handle. So, that is why there is not any one-size-fits-all solution that we can embrace, one that will work all over Europe.

Materials are being graded and categorised into green, red and amber depending on if they technically can be recycled (sorted, washed and re-granulated); if they theoretically have a an aftermarket. Technical and economic feasibility varies by application as well geographic region. Meaning if there is anyone interested in paying money for the recycled content.

These political legislations and new packaging fees have put pressure on the packaging industry. Right now, there is a pull effect leading to a lot of development and innovation within the field. This enables us to get more support and options to choose from than before. The recycling technologies are also developing, and we are following the increasing push for chemical recycling and how it will turn plastic back to plastic or fuel. Today, we work in close development projects with a number of suppliers, who are presenting different portfolios, different polymers, suited for different machines, formats and processes.

Circularity – why is it important?

The circular approach will help us to reach the full potential of all development projects that we have done in the past – and now we are able to close the loop. Being able to pack coffee and other products in a way that is contributing to a circular economy.

In order to succeed, it will take system-level changes to truly achieve sustainable packages. The entire value chain needs to work together to improve the recycling infrastructure, recycling technologies and to create circular value chains. Alongside with initiatives that encourage consumers to continue to recycle their flexible plastic bags.

How far along has the circular packaging project come?

We are moving at lightning speed. A few months ago, we presented the new goals to our suppliers. We rewrote our packaging strategy, and the steering group gave us the approval to continue.

Last month, we tested the first small production of fully recyclable packages made from 50% bio-based polymers. We were able to approve the first small production, its runability and quality, for ground coffee packed in stand-up pouches.

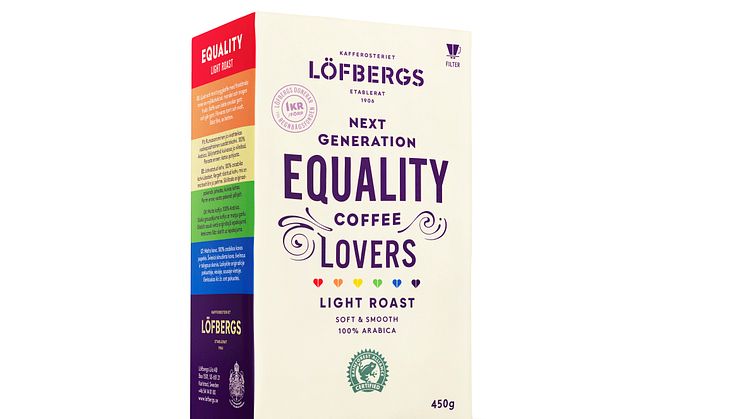

These packages are made of multi-substrate films from polyolefins (called OPP/PE), polymers that are part of the same chemical family. These polyolefins are approved for recycling in Denmark. As we will use it in a Peter Larsen product for the Danish market, it is a game changing package designed for recyclability, 50% bio-based.

We will be able to reduce our plastic consumption, our climate impact and moreover, the new film can be sorted by automatic plastic sorting lines. Recyclers, who handle these polyolefin grades as well as a downstream market for the fraction, already exist.

We are now planning to scale up our production.