Press release -

Groundbreaking: Danish plastic manufacturer develops unique turn valve for the medical industry

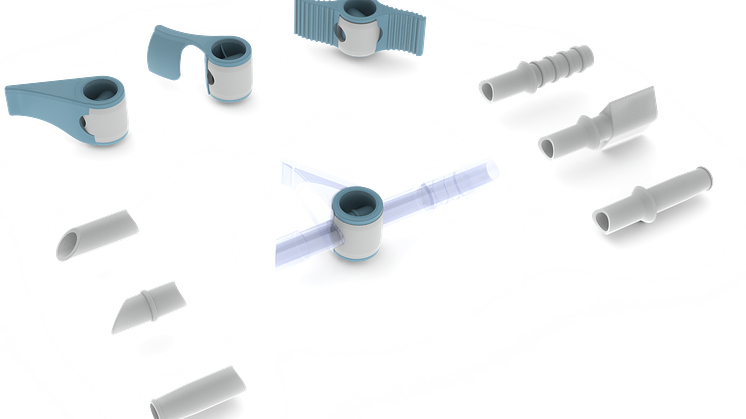

The Danish plastic manufacturer Carmo has designed and developed a unique turn valve for urine collection bags. The valve will be moulded in a single piece, which increases its strength and durability and ensures fully automatic high-volume production in Denmark. The patented valve will be presented at the Compamed fair in Germany in November.

Valve production in the West is under pressure by Eastern manufacturing, where low wages keep costs down. But as the first company in the world, Danish Carmo has now designed and developed a fully moulded turn valve for urine collection bags and other medicine bags. Moulding the valve in one piece means costs are kept low. This makes fully moulded high-volume production in Denmark competitive internationally.

– We will go as far as to say that Carmo SuperValveTM truly is a revolution on the market. We have cracked the code on how to mould a turn valve in one piece, which means that we can cut production time significantly. As a benefit to us we become competitive in an area, where there is a lot of competition, and we’re doing it with a highly durable and safe product, explains Anders Johnsen, development- and technology director at Carmo A/S.

Groundbreaking production increases safety

Besides the competitiveness of high-volume production, there are more benefits in producing the new valve in one piece. Normal valves, which are produced in several parts, are held together with silicone to ensure density. With the new valve, you minimize the risk of leakages because there are no joints, and you also avoid silicone in the production, which is non-biodegradable.

– It’s a clear improvement compared to normal turn valves that we can now produce them in a single piece. We avoid all the intermediate processes where several parts need to be produced and assembled. We have a product with a high level of durability and uniformity, which makes the valve more secure and resistant to leakage, explains Anders Johnsen and elaborates:

– It’s groundbreaking for the industry that we can now reach such a high level of valve safety. At the same time, they meet the ISO 13485 and the MDR-regulation and will be produced in medically certified materials to ensure that safety and leak resistance is guaranteed.

Custom-design presented at trade fair

Carmo’s specialty is custom-designed products that can be produced in great quantities, and Carmo SuperValveTM is no exception. This means that the valves can be produced specifically for various purposes and needs, and thereby to specific industries, which is unique considering that costs and production rates are still competitive.

– It’s a rather simple product with a highly important function for both investors and the end user. That’s why it’s essential for us to be able to offer a safe, quality product that can be custom designed to fulfill the customers’ wishes. We look forward to presenting the valve on the fair in Germany, where potential business partners can see the valve and talk to our team regarding the development and the design of the product, says Anders Johnsen.

Carmo will present the Carmo SuperValveTM at the Compamed fair that takes place in Düsseldorf from the 14th to 17th of November. You can find Carmo at the Danish Exports Pavilion of Denmark, booth 8A, R11.

Visit Carmo’s booth to hear more about the Carmo SuperValveTM and chat with, among others, development- and technology director Anders Johnsen and key account manager Susanne Schannong Lundstrøm about customer-specific solutions, and how the valve can be adapted to exactly your needs.

Read more about the Compamed fair here.

Facts: Carmo SuperValveTM

- - Outlet diameter of 5,9 mm.

- - Withstands pressure of 0,15 bar.

- - Can be sterilized and maintain functionality.

- - Fully validated and ready for clinical tests.

- - Delivery possible in biocompatible materials.

- - PVC- and silicone free.

- Tube connections enables external adjustment for attaching hose connection.

Related links

Categories

Carmo A/S designs, manufactures, and sells in-house produced high-quality injection moulded medical and industrial plastic components. We are experts in advanced injection moulding and Additive Manufacturing – Our expertise lies in 3D-print moulding. With Carmo Print Moulding we offer rapid prototyping, where we design and 3D-print moulds and injection mould prototypes in the correct materials. www.carmo.dk/en/