Press release -

Fascination Formula 1: Which metals are used in the world’s best cars?

Super fast and super safe, that's what Formula 1 cars are. To achieve this, the component materials are selected based of their mechanical properties and density. Because the lighter the car, the faster it is. Carbon fibre is the material of choice. But which metals are used in the car? As advanced as the material is, F1 components are often manufactured on standard CNC machines. Some used lathes from a Formula 1 racing team are currently being sold at an industrial auction.

Formula 1 is fascinating. It is the Champions League of motorsport – the unique combination of technology, speed, precision and competition. The racing series brings together the best drivers and engineering teams with the most complex cars and, of course, the most money. All in all, a single F1 car costs three to four million euros.

A Formula 1 car makes over 1,000 hp. Despite having ten times more power than a standard car, F1 cars weigh only half as much. In 2022, the minimum weight was 798 kg, including the driver. The engine unit accounts for most of this, as it must weigh at least 150 kg according to the regulations. For all other components, as much mass as possible is saved. This is achieved on the one hand by a clever choice of materials and on the other hand by an efficient design. In addition to weight reduction, the focus is always on safety.

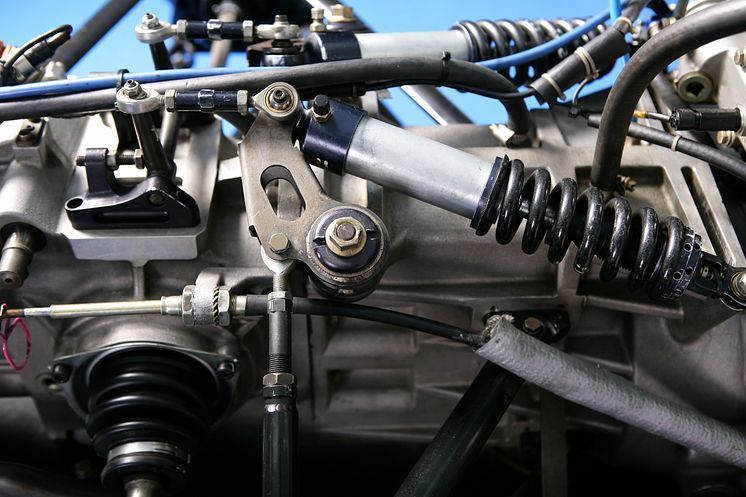

Apart from the gearbox, engine and wheel suspension, a Formula 1 car is largely made of carbon fibre. Carbon fibre is characterised by high stiffness and strength at very low weight – perfect for Formula 1. But with the extreme mechanical and thermodynamic requirements, metals must also be used.

10,000-piece heart: the Power Unit

The power comes from the highly advanced 1.6-litre V6 hybrid engine. These horsepower monsters may only be produced by FIA-approved manufacturers. Currently, Mercedes, Ferrari, Renault and Honda are active in Formula 1. From 2026, there will be six manufacturers: Audi and RB Powertrains/Ford have registered alongside the four established ones. Each F1 team can only source engines from one of these manufacturers and then has the task of building the entire car around that engine.

The power unit of the 2021 world champion car, the Mercedes W12, consists of 10,000 individual parts. The FIA regulations specify in detail which part must be made of which material and how it must be manufactured. The power unit consists mainly of metals. Due to the extensive electronics components, not all of them can be listed. Titanium or titanium alloys are used for many engine parts and for the wheel suspension because it has high toughness, strength and ductility and is corrosion-resistant. To save weight, less heavily stressed components, such as the cylinder head, are made of aluminium. The crankshafts and camshafts are made from a single steel workpiece.

When the cogs are glowing

After the engine, the eight-speed gearbox is the second heaviest component. A driver shifts gears over 2,000 times in the 300-kilometre-long race at Silverstone. That takes its toll on the gear wheels. They are made of high-strength steel and have to be changed after every race. In contrast, the gearbox housing lasts the entire season. It has to be as rigid as possible, as the rear axle is suspended to it. Therefore, it is made of titanium and carbon fibre. The drive shafts are made of steel. For components that are not made by additive manufacturing, any steel alloy is allowed. The less stressed transmission parts are made of aluminium or plastics.

How CNC lathes contribute to the manufacturing of high-performance components

The components of a Formula 1 car must be manufactured precisely and safely in a prototype to small series production. Rapid research and development as well as annual rule changes by the FIA present a further challenge. Thus, the machines must be highly flexible. Commercially available but high-quality CNC machines are capable of meeting these requirements. As spectacular as the components are, the machines are simple.

CNC lathes are used for the manufacturing of rotationally symmetrical parts such as pistons, crankshafts, gearbox shafts, drive shafts and wheel hubs. By using different tools, A wide range of materials can be processed. And because the machines from an F1 racing team are of very high quality and have been properly maintained, they can provide many years of reliable service. If these are replaced by newer systems, they end up on the used machinery market. In this case, an F1 racing team also functions only as a metalworking company.

CNC lathes and machine tools from a Formula 1 racing team are currently available at the industrial auction house Surplex. The auction runs until March 23rd. The almost 50 items are located in Redcar and Cleveland, North Yorkshire, England. The five lathes from HARDINGE and HITACHI are of high quality and known for their precision and robustness. The auction offer is complemented by a large number of equipment (collet holders, drill heads, micro probes, shrink fit holders, jaw chucks and vices). Companies thus have the opportunity to supplement their plant park with flexible production machines. The fascinating past of the offered machines is included free of charge.

About Surplex

Surplex is one of Europe’s leading industrial auction houses and trades worldwide with used machinery and equipment. The 16-language auction platform Surplex.com records approximately 50 million-page views annually. More than 55,000 industrial goods are sold each year at more than 800 online auctions. The company is based in Düsseldorf (Germany) and has offices in 15 European countries. Over 220 employees from 20 different nations generate an annual turnover of more than EUR 100 million.