Pressemitteilung -

Boosting sustainability with top material efficiency and recycling capability: Rethinking Plastics

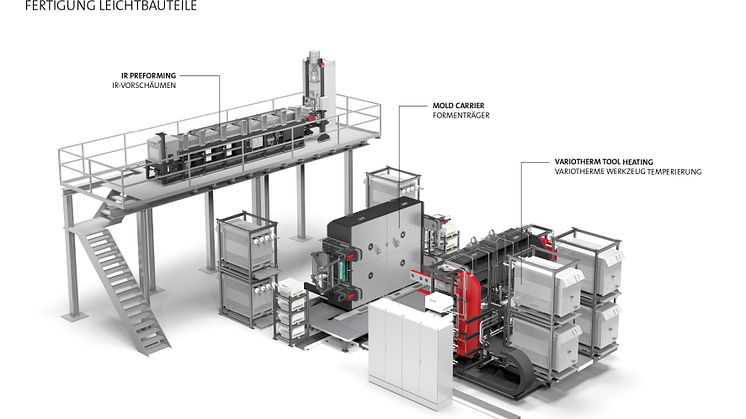

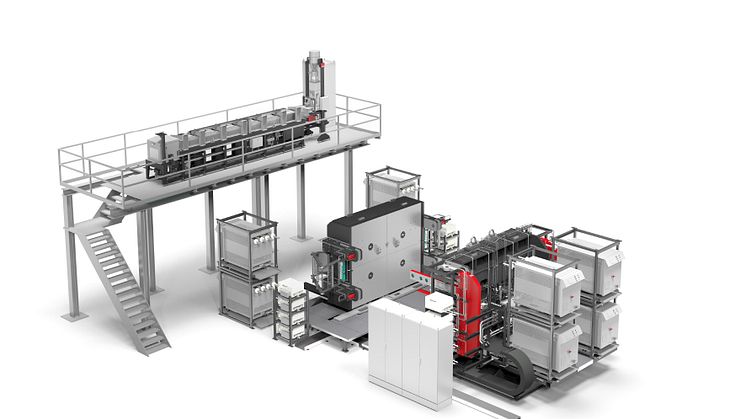

PARAT Technology specialises on light and sturdy plastic components for special-purpose and utility vehicles. To improve the insulating properties and sustainability of these parts, Polyurethane is being replaced by recyclable particle foams. Back-foaming thermoformed parts entirely without the use of steam on a custom FILL plant not only reduced the energy consumption and cycle time. It also facilitates manufacturing sandwich parts with greater stiffness and direct integration of sensitive functional or electronic components.

Plastic parts reduce the weight and fuel consumption of vehicles and thus help to improve their carbon footprint. As a specialist for complex moulded, large-format parts with annual quantities of 500 to 25,000 units, PARAT Technology GmbH + Co. KG develops and produces highly functional plastic sheathing and structural components with complex geometries, primarily for special-purpose vehicles. "Our products combine the highest standards of design and performance, and our particular focus is on sustainable solutions," emphasises Johannes Rosenberger, Head of Sales at PARAT Technology.

Rethink Plastics

The vehicle components manufactured by PARAT Technology are predominantly deep-drawn parts back-foamed with polyurethane (PU). In order to further increase the sustainability of its products, PARAT Technology looked for an alternative to non-recyclable PU foams. Particle foams such as EPS, EPE or EPP are expanded on site and therefore have an extremely low transport volume. They enable complex shapes, have an extremely low density and very good insulation values. This makes them ideal for the requirements of camping vehicle construction, for example.

A new processing method

The steam used in conventional processes causes high energy consumption, long drying times and prevents the integration of sensitive inserts. This is why the globally active Austrian mechanical engineering company FILL developed an all-electric, entirely steam-free manufacturing process for particle foam processing. In its first stage, a patented infrared pre-foaming system, the volume of the microgranulate is increased by a factor of 50 using infrared radiation.

Thanks to the dry process, further processing in the moulding tools can take place immediately afterwards. For this, PARAT Technology uses variothermal moulding tools. Equipped with several heating circuits, these allow producing parts with zones of different strengths in a single shot. The material remains dry and free of inhomogeneities. The moulded part is solidified by cooling the moulding tool, so parts can be removed manually.

New and more sustainable parts

In a process patented by PARAT Technology, parts are created as a sandwich between two deep-drawn bodies forming the outer and inner walls. Due to the low pressure and heat values in the foaming process, particle foam moulded parts can also be functionalised in the FILL system by integrating inserts such as fastening, reinforcing or decorative elements. "The newly developed dry production process for particle foaming enables us to produce completely new, more sustainable panelling components," explains Tobias Schmid, Head of Development at PARAT Technology.

About Fill

FILL is a leading international machine engineering company based in Gurten, Upper Austria. With sophisticated high-tech systems and custom manufacturing solutions for metal, plastics and wood, Fill makes its customers the best in their fields. The automotive, aviation, sports and building industries all benefit from Fill's expertise. Fill is 100 per cent family-owned, has more than 1,000 employees and achieved a turnover of around 210 million euros in 2023.

For more information, visit www.fill.co.at